ChemBeads: Improving Artificial Intelligence Through Human Ingenuity

Discovering a new medicine isn’t easy. When robots couldn’t help, three scientists found a way.

ChemBeads: chemistry coated in glass

What do tiny glass beads, a powder mixing machine and solid chemicals have in common?

Not much. Until a group of AbbVie chemists had an idea that could shorten the screening time for some compounds from weeks to days.

Long before there is a medicine, there is a compound. Or rather, thousands of compounds that must be tested in order to find the special few that could one day become a medicine. It’s a long and resource-heavy testing process to identify these “lead compounds” that could possibly be converted into a new medicine.

To test these compounds, scientists first have to make them. Unfortunately, finding the conditions necessary to make the desired compounds can often be a bottleneck, in part due to the limited amount of material available and a lack of technologies to screen diverse conditions efficiently and effectively. In other words, it adds a time consuming, resource-heavy step to what is already a painfully slow journey from scientific discovery to potential treatment.

In robots v. solids, solids usually win

The issue chemists run into is that not all compounds are alike in terms of their physical properties; because of this, robots can handle some better than others.

Like nearly everything these days, artificial intelligence was implemented to improve the screening process. But the robots who expedited the screening do better with liquids, which are uniform. Solids have proved more challenging. While liquids are pretty much homogeneous and easy for robots to read, solid chemicals can be fluffy, crystalline, chunky, etc.

Lucky for the robots, human creativity found an answer. Using glass beads and a dry mixing machine, a group of AbbVie chemists – Noah Tu, Ying Wang and Amanda Dombrowski, all members of AbbVie’s high throughput chemistry (HTC) team – came up with an idea that could help the robots do their work.

The idea was born from frustration, which can be a powerful motivator, Dombrowski says.

“The only way for the robots to handle solids was to dissolve the compound into a liquid, which took a lot of work and many times could complicate the reaction screen process,” she says. “So there was really no way to dispense solid compounds easily. We realized that if we wanted a better solution, we had to find it ourselves.”

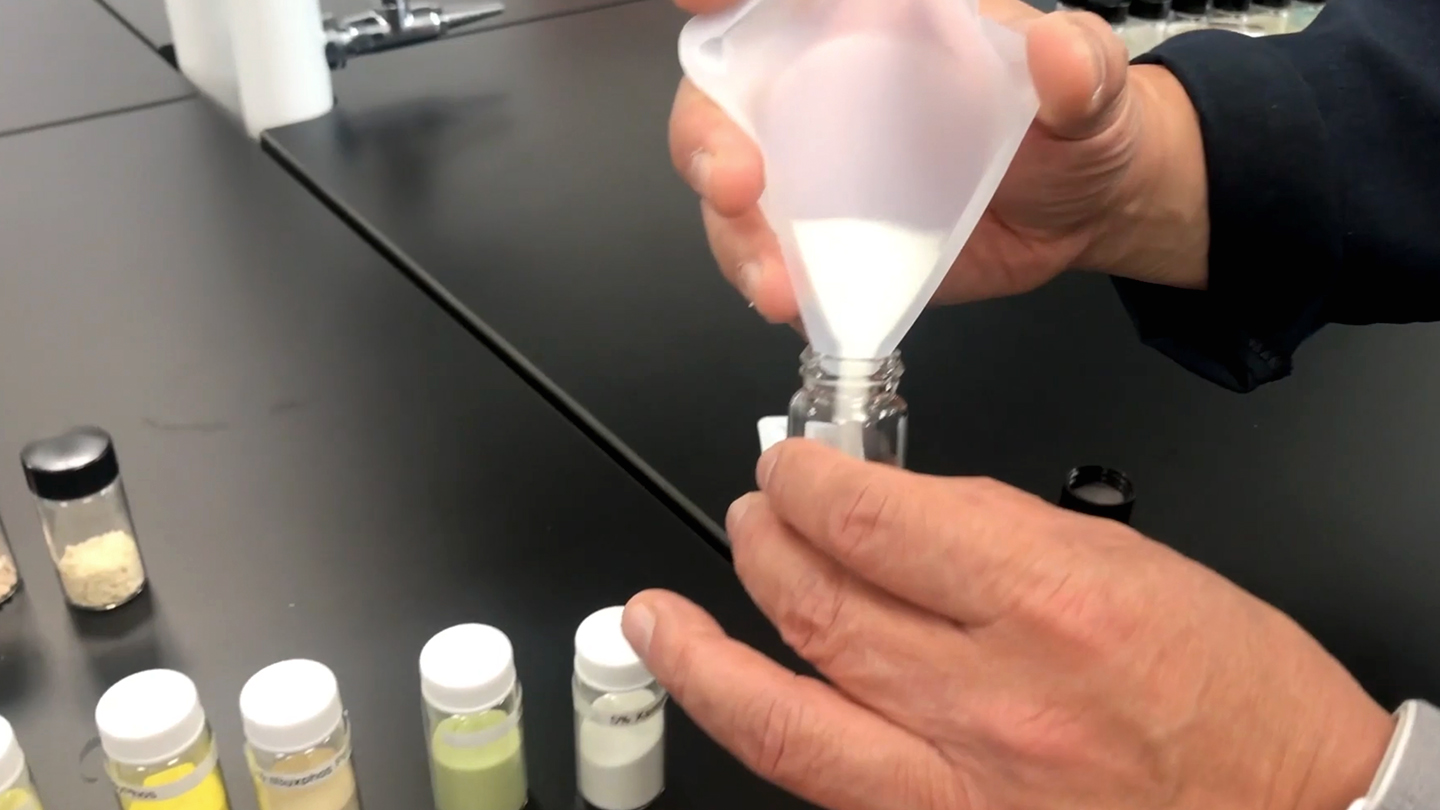

After a few false starts, the team was inspired by a process where medicines are mixed with other inert materials to improve their solid characteristics. They found that glass beads can be coated with solid chemicals by combining them in a dry mixer. Solid chemicals are often very different from each other in terms of physical characteristics, but the chemical coated beads have very similar features, which makes a robot’s job much easier.

Watch Noah Tu, M.S., senior scientist, discovery chemistry and technologies, AbbVie demonstrate the process:

Making a good idea better, a millionth of a gram at a time

One ChemBead weighs one millionth of a gram, five percent of which is the active chemical, with the remaining 95 percent consisting of the glass bead.

Using automation to dispense these chemically coated glass beads – a process dubbed “ChemBeads” by the chemists who invented it - accelerates and simplifies the process of finding conditions to make a compound. Because of this, these tiny beads are getting a lot of attention.

“Good science is all about coming up with a good idea and making it better,” Noah Tu, M.S., senior scientist, discovery chemistry and technologies, AbbVie says. “That’s exactly what we did. We came up with the idea of ChemBeads in 2016 and we’ve been refining and improving the technology ever since.”

Word of ChemBeads spread fast within AbbVie’s chemistry labs, says Anil Vasudevan, Ph.D., senior director, discovery, who over sees the team that includes Tu, Wang and Dombrowski.

“A few years ago, no one had ever heard of ChemBeads, and today it’s a common phrase in our labs,” Vasudevan says. “When this team first told me about ChemBeads, I thought it would have limited applicability. But they believed in this idea and never gave up. I’m inspired by their determination to find a practical solution to a problem that has plagued drug discovery scientists for a long time.”

In an industry where getting treatments to patients faster is imperative, ChemBeads are helping AbbVie chemists find a way to make compounds in two to three days instead of weeks. And ChemBeads are screened with small amounts of material, also saving resources. To date, the high throughput chemistry team has made more than 350 ChemBeads and found reaction conditions for chemistry teams in Illinois, Massachusetts, Germany and California.

“We are the first stop of the drug discovery process and our chemists are charged with screening compounds as quickly as possible so they can move on in the drug development process,” says Tom Hudson, M.D., vice president, discovery, AbbVie. “I’m proud of this team. Their determination really proves that creativity powers science and technologies.”

Media inquiries:

Email: [email protected]